Add to Cart

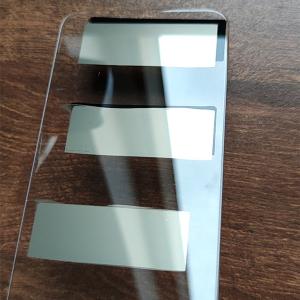

Mirror-effect Ink

Introduction

The customized mirror gold ink is mainly used for printing on the glass cover of cell phones, to get the mirror-effect of gold, the same as the effect of gold metallic color. It has excellent adhesion on glass substrate, it is recommened used for characters and patterns printing.

Customized Mirror Silver Ink Instructions

| Main components | Various synthetic resins, solvent and treated metal powder |

| Particle size | 2-5 microns |

| Printing substrate | Glass cover sheet |

| Surface drying | 150°C for 5 minutes |

| Solid drying | 150℃ for 30 minutes |

| Mesh | 350 mesh/inch polyester mesh |

| Scraper hardness | 70 ° ~ 85 ° |

| Dilution | With thinner, it must be fully stirred evenly before use |

| Washing | Wash the mesh with thinner |

Performance

Application

Precautions for Printing Processes

Storage

The product should be stored in indoor dry place (Air humidity of 75% or less)

Packing

25, 50, 200 kgs/barrel

Special Tips

This material is complied according to our existing technology and experience, the technical advice provided is sincere, but it is not guaranteed to be used in all samples and formulations, all the data are for users reference only.